DIY Miata Shock Mount kit

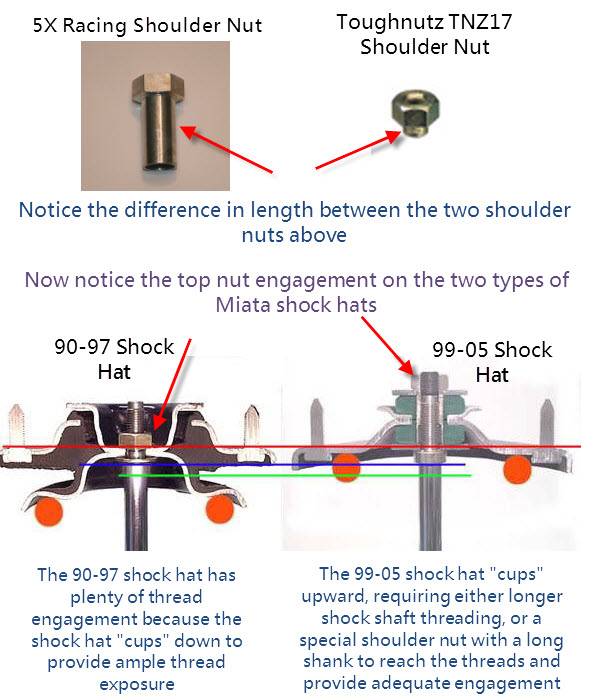

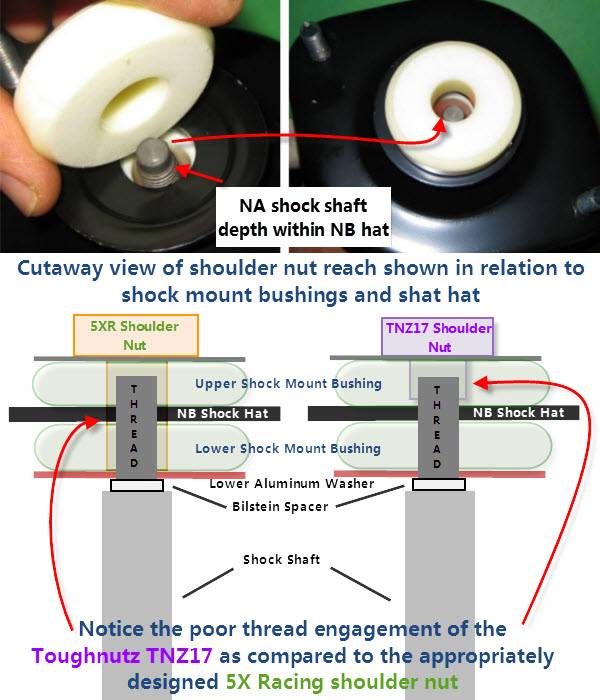

We have been getting emails recently about the use of Toughnutz TNZ17 shoulder nuts in Miata shock mount kits, and in each of those email responses I warn on why you shouldn't use the Toughnutz shoulder nuts. Nothing against Toughnutz (they're actually nice hardware for good prices!), but it's simply not the right solution for the job at task. We've actually tried making our own NB to NA conversion kit years ago before we took over manufacturing and distribution of the Fat Cat Motorsports brand, and this is one of several areas where we fell short. The shoulder nuts we manufacture for the shock mount kits we offer are specially designed to plunge deep into the shock hat/mount assembly and properly affix to the shorter threaded portion of the NA shock shaft. The Toughnutz (sounds so funny to say!) are just too short for the depth needed, and while they "might" latch onto the shock shaft, there's just not enough threads there to get a confident feeling about such a highly stressed part, holding together a VERY important part of your vehicles suspension system!

Our shoulder nuts are custom manufactured to achieve the proper depth and not off-the-shelf like a Toughnutz TNZ17, which why the cost is high. The key component to mounting the NA shocks to the NB hats is the shoulder nut. While it might be possible to squeeze a nut onto the shock with thinned bushings (like the "MotoIQ method") via a Toughnutz shoulder nut, this is a highly stressed connection and the lateral movement in this area of the shock mount assembly will allow at the very top of the shock shaft to wiggle back and forth slightly - like bending a paper clip back and forth - and eventually it will break. This movement is slight, but still more movement than the shock was designed for, so in time it could break while driving or at the very least garble up the small amount of thread the nut is holding. The thickness of the stock rubber bushings (and our shock mount bushings) allow proper flex range, and the length of our shoulder nuts ensure the proper support of the shock shaft by plunging into the middle of the assembly, not just the very tip like a too short Toughnutz shoulder nut would.

Below are some diagrams we made up to help visualize this. I'm sure this will put things into perspective for you, and hopefully reinforce the notion that having enough thread engagement is important, and while we wish we could offer you 10 shoulder nuts for $24, there's no way as our cost to produce our shoulder nuts is WAY over that of the Toughnutz apparently!